At Smartech, we specialize in small batch manufacturing, offering a variety of processes to adapt to our clients’ needs. These processes include thermoplastic injection, CNC machining with aluminum, Zamak and plastics, stamping of steel or aluminum sheet parts, and extrusion and machining of aluminum parts.

Thermoplastic Injection

This is a process where plastic is heated until it melts, then injected under pressure into a mold. This mold is cooled, solidifying the plastic into the desired shape. Finally, the plastic part is removed from the mold. This is the thermoplastic injection process, a technique we use at Smartech to create high-quality plastic parts.

Benefits of thermoplastic injection:

– Production speed: Allows for rapid manufacturing of parts.

– Design flexibility: Can produce intricate and complex shapes.

– Efficiency: Reduces the number of parts and assembly time.

This process is used in the manufacturing of components for the medical device industry, automobiles, and prototypes for the technology industry, among others.

CNC Machining

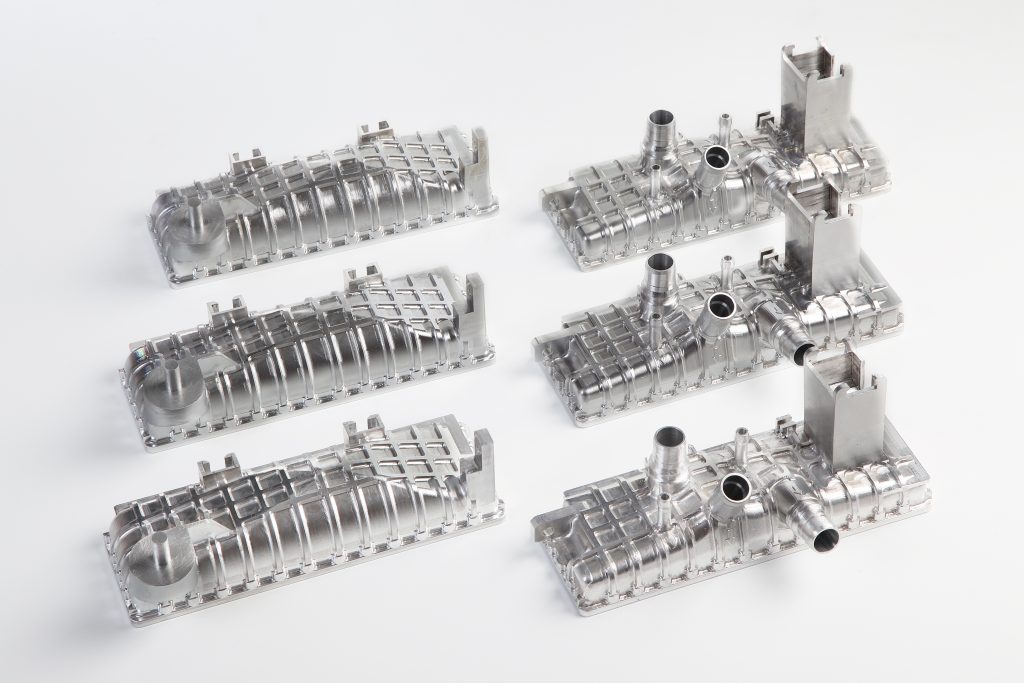

On the other hand, CNC (Computer Numerical Control) machining is a manufacturing process that uses computer technology to control the movement of cutting tools. In this process, a CAD (Computer-Aided Design) design of the part is created, which is then converted into a CNC program. This program controls the cutting tools to produce the part.

Benefits of CNC machining:

– Precision: Can produce parts with high precision and consistency.

– Flexibility: Can produce a wide variety of parts.

– Efficiency: Reduces production time and labor costs.

CNC machining is used in the manufacturing of parts for the aerospace industry, the energy industry, and the defense industry.

Stamping of Steel or Aluminum Sheet Parts

As for the stamping of steel or aluminum sheet parts, this is a manufacturing process that uses presses and molds to shape metal sheets. A metal sheet is placed in a press, and the press applies pressure on the sheet using a mold. In this way, the metal sheet is deformed to take the shape of the mold.

Benefits of stamping steel or aluminum sheet parts:

– Mass production: Allows for rapid manufacturing of large quantities of parts.

– Low cost: Reduces production costs compared to other manufacturing processes.

– Versatility: Can produce a wide variety of shapes and sizes.

Stamping is used in the manufacturing of components for the construction industry, the heavy machinery industry, and the home appliance industry.

Extrusion and Machining of Aluminum Parts

Finally, the extrusion and machining of aluminum parts is a manufacturing process that involves forcing aluminum through a hole to create a specific shape. Then, the extruded part is cooled and cut to the desired length. Finally, the part is machined to give it the final shape.

Benefits of extrusion and machining of aluminum parts:

– Flexibility: Can produce a wide variety of shapes and sizes.

– Efficiency: Reduces production time and labor costs.

– Quality: Produces parts with high precision and surface finish.

Extrusion and machining of aluminum are used in the manufacturing of components for the construction industry, the transportation industry, and the renewable energy industry.

At Smartech, we are proud to offer these high-quality manufacturing services to meet our clients’ needs. With our experience and advanced technology, we can produce high-precision parts in small batches, providing customized solutions for a wide range of applications.