3.2 MECHANICAL PRODUCT DESIGN

We design a wide range of mechanical parts involving milling, turning, grinding, and EDM machines.

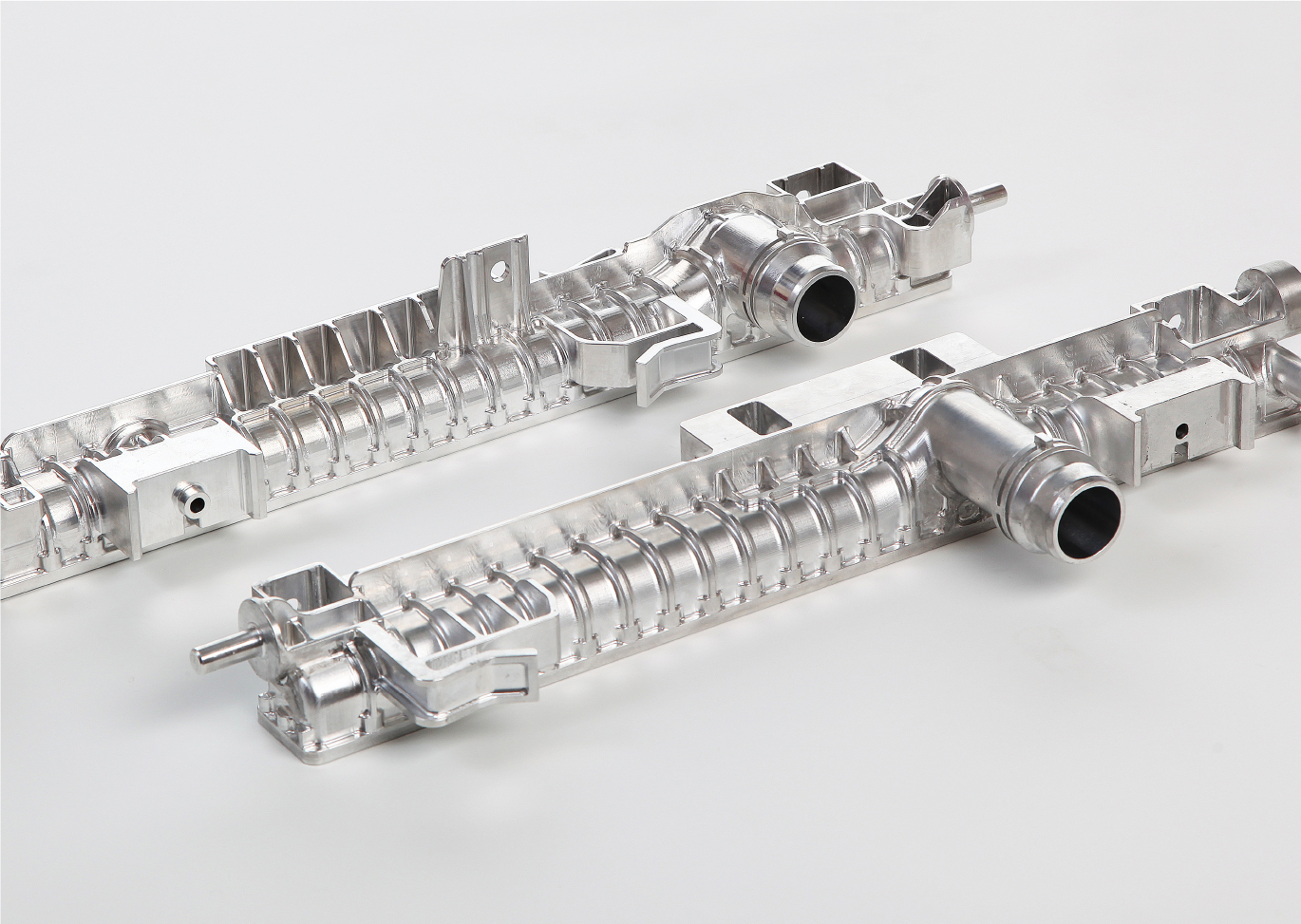

We work with CNC-machined parts and injection-molded parts, such as plastic or die casting.

We also offer stamping and laser cutting for prototype parts.

We can produce the following products tailored to your needs:

Gauges, automatic gauges,

and dimension-checking fixtures

We design and manufacture gauges for the automotive industry and automatic stations to provide 100% production control.

Moulds Design for LPM

Low-pressure molding is an innovative process in which electronics are imbedded into a predesigned mold to protect them from environmental factors such as moisture, dust, vibration, and handling.

Testing tools

These are used to directly check part sizes, position characteristics, etc., in order to facilitate quality inspections and improve production efficiency.