Smartech’s expertise in mold design for the low-pressure molding (LPM) process distinguishes us from other industrial specialists. Our mold design service aims to develop specific solutions for the industry by combining innovation, precision, and efficiency.

Low-pressure molding is a crucial process in component manufacturing, especially in industries such as automotive, aerospace, and electronics. The design of molds for this process is an art that requires a high level of precision and technical knowledge. At Smartech, we focus on developing molds that not only meet the specific requirements of each project but also optimize production and the quality of the final product.

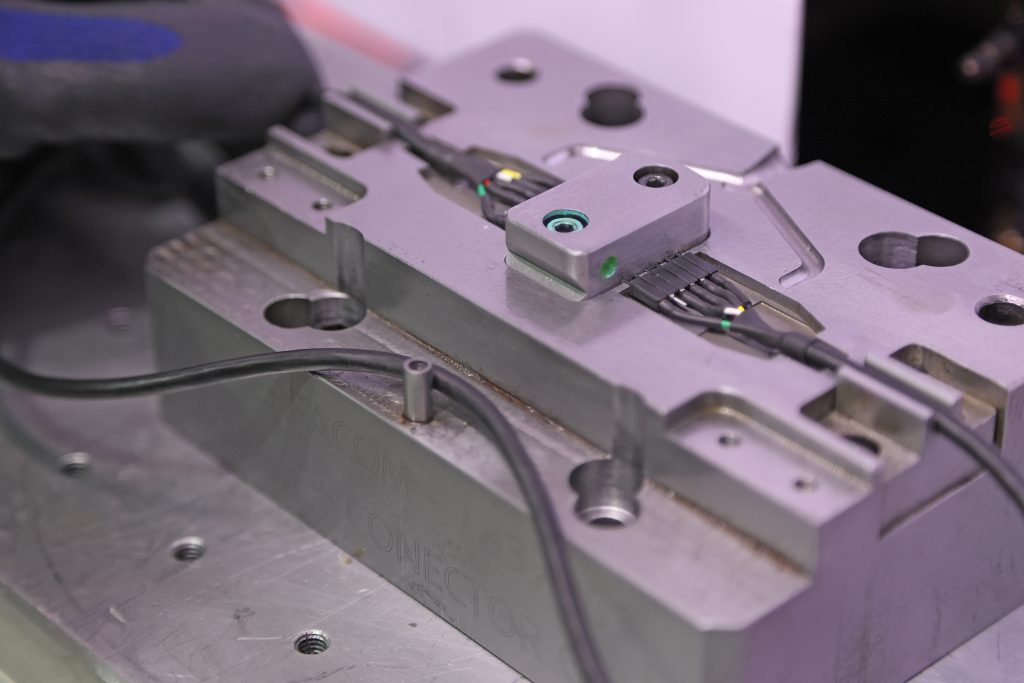

Our molds are designed and manufactured using cutting-edge technologies. We can create detailed and precise designs by using computer-aided design (CAD) software and 3D modeling tools. Virtual simulation of the LPM process allows us to anticipate and solve potential problems before mold manufacturing.

We are able to meet the specific needs of our clients by focusing on customization because each project is unique. Our molds are designed to be adaptable to a variety of applications and materials, resulting in versatility and adaptability in the production process.

The design of our molds is based on the importance of quality and durability. Our use of high-quality materials and strict manufacturing standards ensure that each mold is both efficient in its function and able to withstand the demands of continuous production.

Collaboration with our clients is key in the design process. Our collaboration ensures that the final mold design perfectly aligns with their expectations by understanding their requirements and objectives. We also provide comprehensive technical support throughout the entire design and manufacturing process.

Smartech’s mold design for LPM is not just a specialty; it is a demonstration of our commitment to innovation and excellence in engineering. Our ability to create specific solutions for the industry, combined with our focus on quality and customization, places us at the forefront of mold design for LPM, helping our clients achieve their production and quality objectives.