The electronics industry is constantly challenged to innovate and enhance the durability and efficiency of its products. Smartech’s innovative SmartMelt machine is the perfect solution for low-pressure overmolding, which offers superior results in the manufacturing of electronic components.

Our innovative approach relies on the SmartMelt machine. The precision, energy efficiency, and design flexibility of this advanced low-pressure overmolding system are unmatched. SmartMelt protects delicate electronic components while also allowing for the creation of more robust and visually appealing electronic devices.

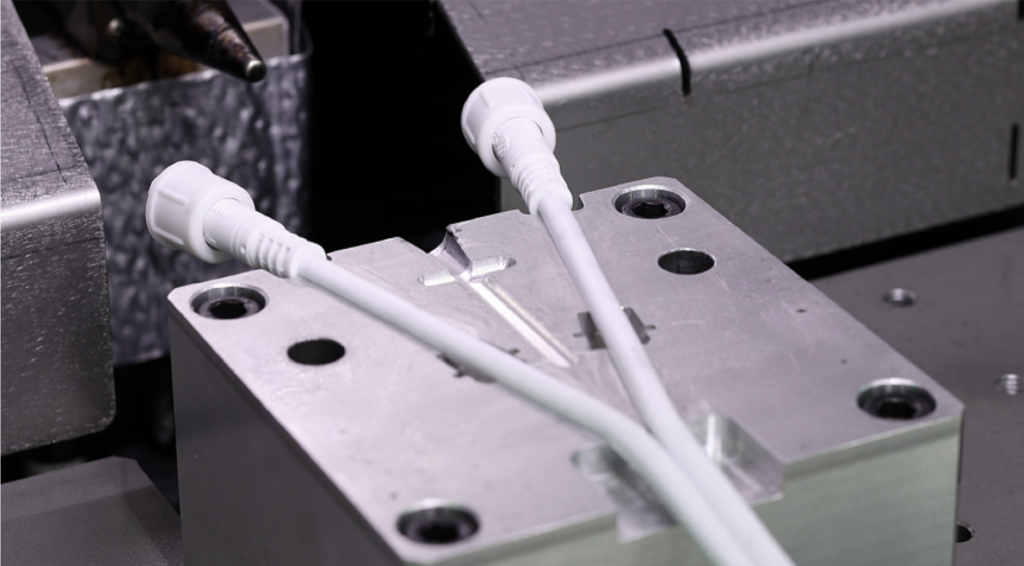

Low-pressure overmolding is a manufacturing process in which plastic materials are injected around an insert, which is usually an electronic component, at lower pressures and temperatures than usual. This method is perfect for covering delicate electronic components, protecting them without compromising their integrity.

Benefits of Low-Pressure Overmolding

Delicate components require protection

The primary benefit of low-pressure overmolding is the superior protection it offers for electronic components. This process uses materials to form a protective barrier around the component, keeping it safe from external factors such as moisture, dust, and temperature variations. This is especially important for devices that are used in challenging conditions.

Resistance to impact and vibration

By using low-pressure overmolding, components can resist impacts and vibrations more effectively. Electronic devices used in industrial environments or mobile equipment where shocks and vibrations are common require this essential feature. Encapsulating the components reduces the risk of internal damage and improves impact absorption.

Extended Durability

The lifespan of electronic components is significantly increased by this technique. The components can maintain their functionality and efficiency for a long time due to their protection from environmental and physical factors, which reduces the need for frequent repairs or replacements.

Design Flexibility

The design of electronic components can be more flexible with low-pressure overmolding. Complex shapes and sizes can be experimented with by manufacturers, which would be impossible or difficult with traditional manufacturing methods. The creation of more ergonomic and aesthetically pleasing devices is possible thanks to this flexibility.

Production Efficiency

In terms of time and cost, the low-pressure overmolding process is effective. Minimizing the risk of damaging components during production results in reduced waste and optimized manufacturing time. This results in higher production efficiency and, consequently, cost reduction.

Sustainability

Compared to other manufacturing methods, this technique is more sustainable. By operating at lower temperatures, energy consumption is reduced. The process’s precision reduces the amount of wasted material, which contributes to more eco-friendly production.

Use Cases

Smartech has successfully used this technique to protect sensors in the automotive industry. The sensors that are essential for the safety and performance of vehicles are always subjected to extreme conditions. Low-pressure overmolding has made these components more resilient to temperature variations and impacts, resulting in reliable operation.

In mobile devices, electronic components are encapsulated in another case. Due to the need for thinner and lighter devices, low-pressure overmolding has been crucial in safeguarding internal components without adding too much volume or weight.

Low-pressure overmolding, powered by Smartech’s SmartMelt machine, is a revolutionary technique in electronic component manufacturing. Our commitment to innovation and engineering quality at Smartech is consistent, ensuring that our customers are always at the forefront of technology.